From concept to reality, Antaya Technologies Corp. offers product development services for on-glass connectors and wire harnesses for any application.

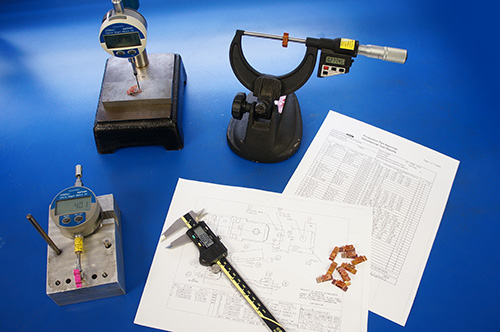

Antaya’s manufacturing facilities employ an unmatched level of vertical integration, with capabilities from solder casting, reflow, rolling, slitting and stamping to welding, injection molding, fluxing, assembly and tooling. Being vertically integrated enables us to maintain strict control over the quality of our products and allows us to respond quickly to our customers’ needs.

Our Product Development teams ensures your product meets your precise standards. Whether a product modification or a new product from the ground-up, Antaya is ready to carry your concept through from concept to completion.